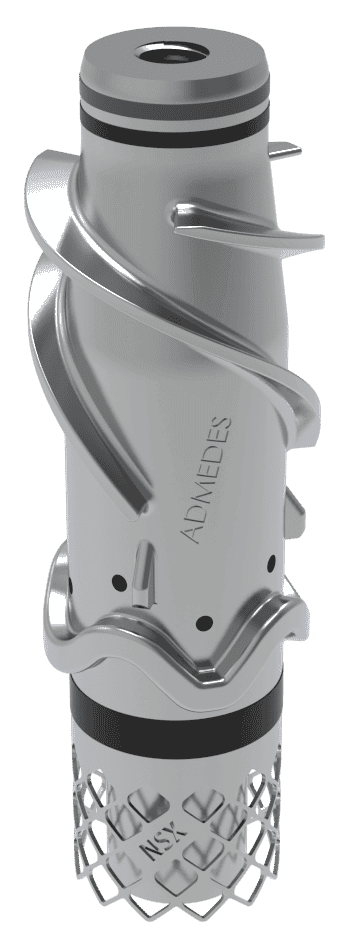

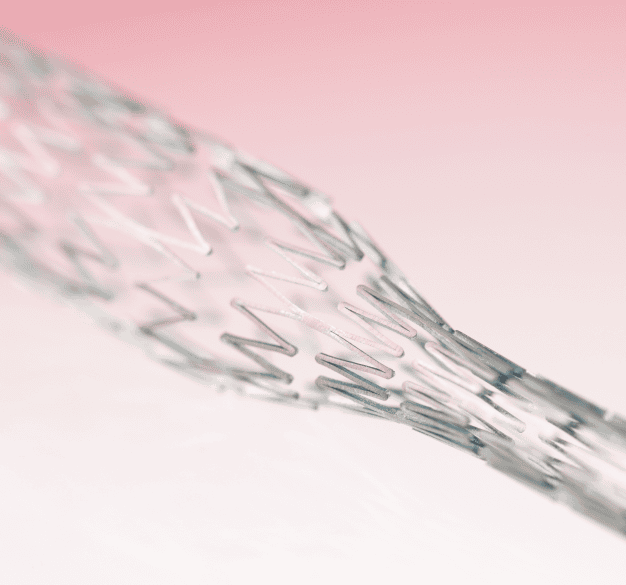

NSX is well known for its highest precision laser processing with cutting as well as ablation possibilities based on our ultra-short pulse technology (USP)

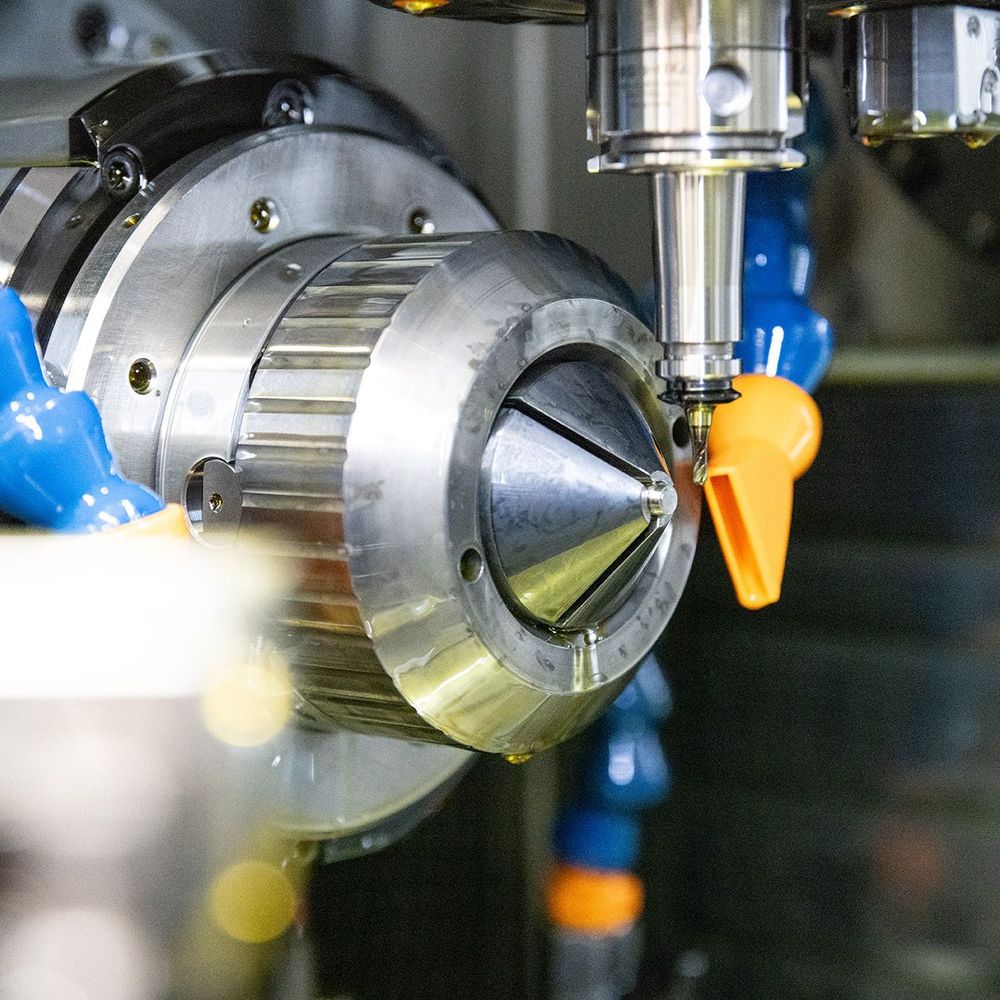

CNC-MACHINING

7-Axis CNC milling machines let us create the most complex freeform surfaces, including slender, highly detailed parts, with the extreme precision that many medical applications require.

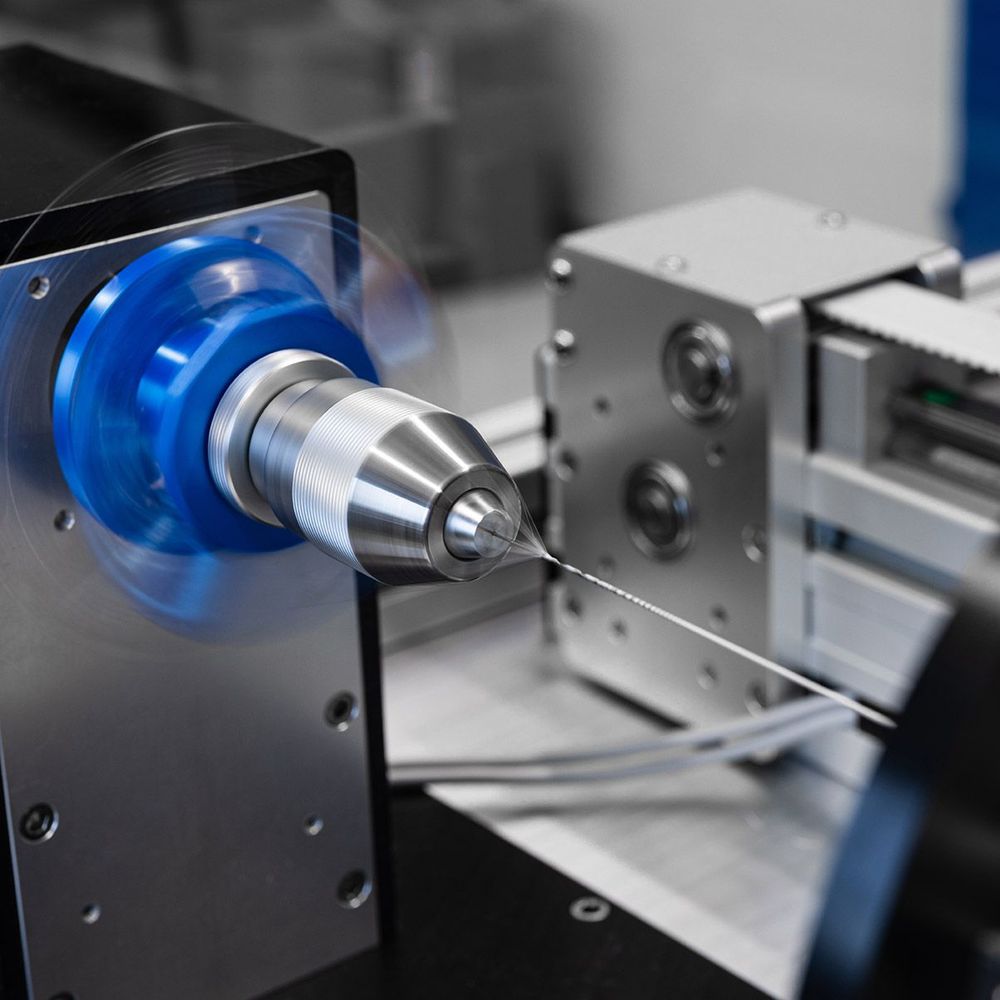

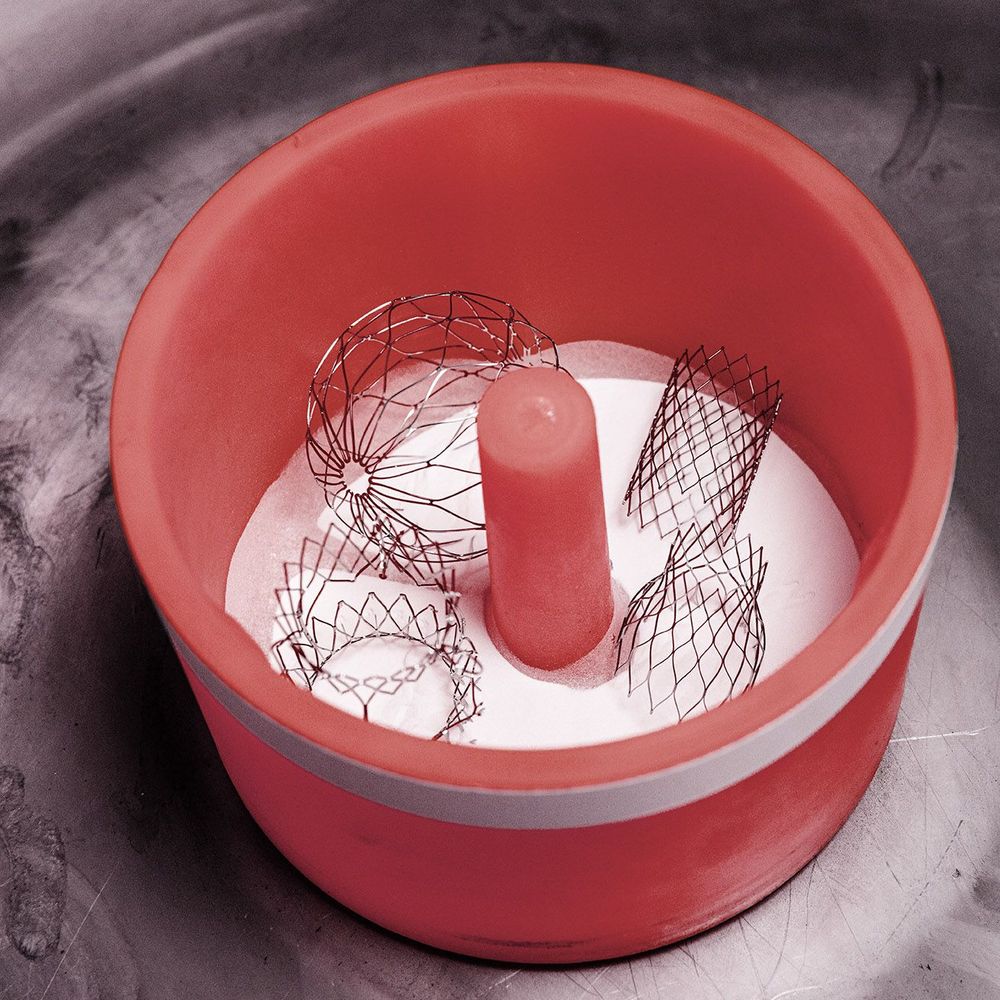

COILING

NSX also offers automated NC-controlled multifilar coiling for coils with a length of up to 2.200 mm

TUMBLING

Tumbling can be applied to achieve superb edge rouding and surface smoothening of your device

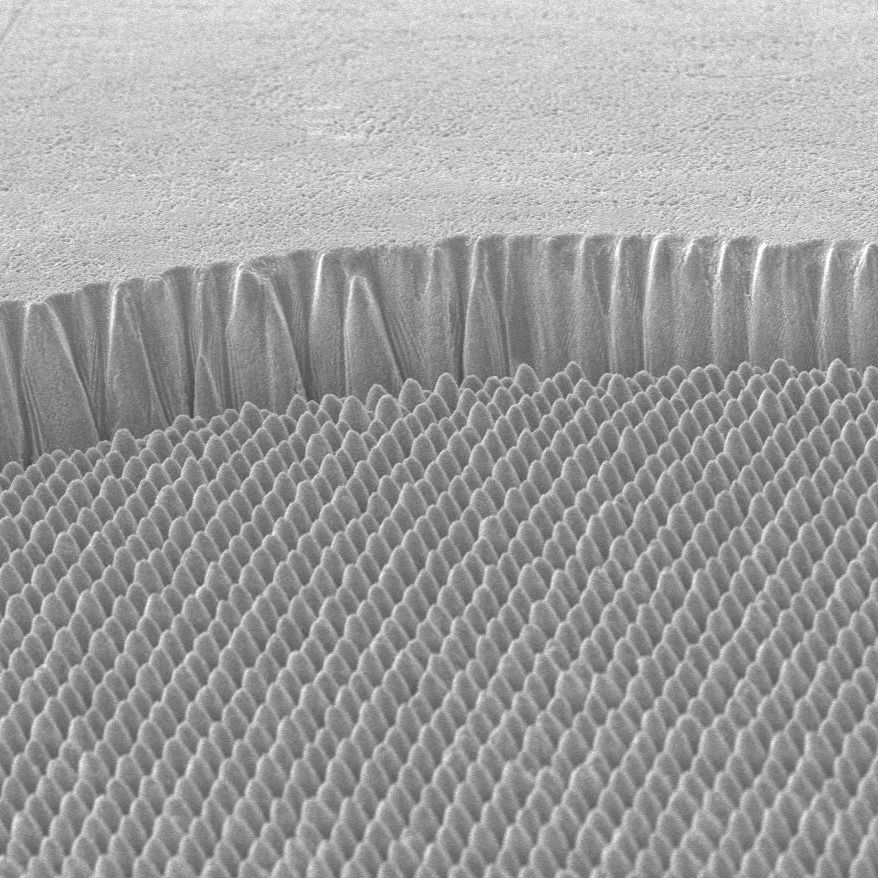

SURFACE STRUCTURING

NSX is able to modify your component surface to support bonding operations or enhance endothelialization of your device

HEAT TREATMENT / ANNEALING

In order to set the required mechanical parameters we offer different kinds of heat treatrment / annealing technologies such as liquified salt furnaces or air furnaces

SURFACE TREATMENT

NSX has best in class surface finishing methods available with Ra < 0,10 µm on finished components, including mechanical, chemical and electrochemical processing (incl. chemical passivation)

ASSEMBLY

We also offer component assembly with welding and glueing operations and optional clean room capability

INSPECTION

Besides conventional measurement technologies as well as 5 axis automated measurement systems, NSX uses Micro-CT 3D imaging, which enables us to measure freeform designs in addition to contours hidden from direct view to detect deviations down to the micron level.

Facts at a Glance

01

Direct access to raw materials

02

Initial samples delivered within 1 week

03

Onsite development workshops

04

High-volume (automated) production line

05

Advanced technologies

(milling, laser, surface treatments, inspection, assembly)

06

Experienced, highly specialized engineering team

07

QA standards with state-of-the-art tools (DFM, SPC)

NSX Services

We live up to a professional project management culture, which starts with the initial contact and communication. Our dedicated team of experts are your perfect partner to manufacture initial samples within less than a week and bring your ideas to full scale (automated) production.

The accelerator for your project are our technical workshops. Multiple design iterations can be manufactured and evaluated onsite within 2-3 days.

Additional engineering support services such as scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDX), mechanical testing and metallography do support your project whenever it is required.

Our quality standard is driven by ISO13485 and we use best practices, such as Lean Six Sigma tools, design for manufacturability (DFM) and statistical process control (SPC), to ensure a smooth transition from development phase to full-scale (automated) production of your components.

Are you interested?

Please contact us for more information.

Contact now

Hauptsitz Deutschland

ADMEDES GmbH

Rastatter Str. 15

75179 Pforzheim, Germany

U.S. Subsidiary

ADMEDES Inc.

2800 Collier Canyon Road

Livermore, CA 94551, USA

Costa Rica Subsidiary

ADMEDES S.A.

Edificio A1 (Gebäude A1)

Parque Industrial Zeta'

Cartago, 30106, Costa Rica'